Clean Burn Waste Oil Boiler

Let Master Burn show you how you can get

FREE Heat with a Clean Burn waste oil boiler.

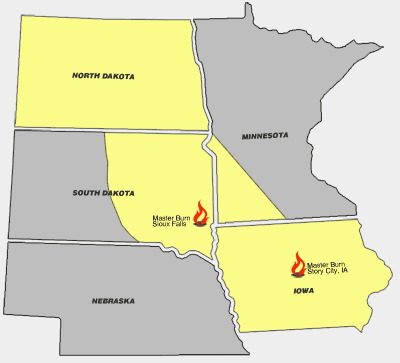

The Clean Burn waste oil boiler system has been designed to efficiently generate hot water by recycling waste oil to provide free heat. Master Burn is the Midwest Clean Burn dealer and we offer unmatched system design, factory installation, staff training and long term service to help you get the best return on your waste oil recycling investment.

Applications

Clean Burn waste oil boilers are used in car wash facilities, they easily connect to space heating, in-floor heating and baseboard heating systems. They are also used to provide heat for ice-melt applications. They are UL Listed for central heating systems, have been awarded the Energy Star Partner designation, and meet all national fire and safety codes.

Fuel Options

Your Clean Burn waste oil burner is EPA Approved to burn a wide variety of used oil products, including crankcase oils, automatic transmission fluid and hydraulic fluid. It's also designed to burn regular #2, #4 and #5 fuel oils to give you unmatched flexibility.

Designed to Wring Out More Energy from Every Drop of Oil

The Clean Burn Coiled Tube Boiler design includes a patented burner engineered to burn waste oils, this burner automatically adjusts to the wide variety of fuels found in typical waste oil.

For efficiency, only a low mass of water is held in the boiler. This means faster start-ups and reduced stack loss. Clean Burn boilers also use a three pass heat exchanger to capture even more savings.

Flexible Installation Options

Each unit can be used as a single boiler unit, or combined to create larger systems. Clean Burn waste oil boilers also feature a narrow cabinet design to offer wider installation options. And Clean Burn makes installation easier by delivering your boiler with all wiring and plumbing in place and ready to connect to your distribution system.

The Lowest Maintenance in the Industry

Clean Burn has slashed waste oil boiler maintenance by 80%. Some competitors require 2 hours of maintenance for every 400 hours of operation! A Clean Burn waste oil boiler will need only 30 minutes of care for 1000 hours of operation.

The reason we require so much less maintenence is that our heater block, atomizer and combustion mechanism are designed for long service life. And instead of disassembling whole burner system to clean it, the Clean Burn system simply swings open for full access.

With Clean Burn Coil Tube Boilers, you spend 30 minutes cleaning every 1000 hours of operation. With competitive units, you spend 2 hours cleaning every 400 hours of operation.

Call Master Burn at 605-543-5817 to find out how to go green with a Clean Burn furnace or boiler.

Clean Burn Waste Oil Boiler Models from Master Burn:

Prices and specifications are subject to change. Not responsible for errors, omissions, and changes. Please call us for clarifications.